ITALCOM SRL

Registered office: Via A.Bianchi, 8 - 37045 LEGNAGO (VR) – Loc. S. Pietro;

Operational/administrative office: Via Sansovino 4 - 37053 CEREA (VR)

Tel. 0442 621886 Fax 0442 1941400,

email: nikita@italcomsrl.eu

VAT and Tax Code: 03548510233

© 2025 ITALCOM SRL | VAT 03548510233

Privacy policy | Cookie policy

What are they?

The bottle capsuling machines are devices used in the packaging industry to apply the capsule (or shrink capsule) on the top of the bottle. The capsule, usually made of plastic or aluminum, serves to seal the neck of the bottle, protecting the cap and ensuring the integrity of the product. In particular, they are widely used for wine, sparkling wine, liquor, and other beverages, as well as in some food or pharmaceutical sectors.

The capping has a function of protection, safety, and presentation of the product, as well as ensuring that the content is not tampered with before opening.

What do we offer?

1. Manual capping machines

Operation: These machines are suitable for small productions and for wineries or laboratories that do not require high volumes. The operator manually inserts the bottle and the capsule, while the machine performs the capsule application process.

Features: More economical and simple to use, they are ideal for artisanal or low-capacity productions.

Advantages: Low cost and ease of use.

Disadvantages: Low productivity, therefore not suitable for high productions.

2. Semiautomatic capping machines

Operation: In these machines, the operator manually loads the bottles and capsules, but the application and sealing process is largely automated. The operator can adjust parameters such as temperature or pressure to suit the type of capsule.

Features: Suitable for small and medium productions, semiautomatic machines are faster than manual ones and offer greater precision.

Advantages: Greater productivity compared to manual models, with contained costs.

Disadvantages: Still require human intervention to load bottles and capsules.

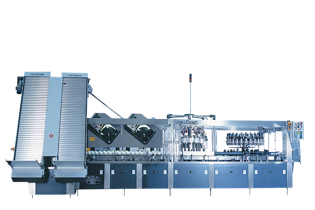

3. Automatic capping machines

Operation: Automatic machines manage the entire process without the need for human intervention, from loading the bottles to applying and securing the capsule. These machines can be integrated into fully automated bottling lines.

Features: They are designed for high production volumes and can apply different types of capsules, including shrink, shield, or screw cap. They can be configured to fit bottles of various shapes and sizes.

Advantages: High production speed and ability to handle large volumes, reducing the risk of errors and increasing efficiency.

Disadvantages: High cost and need for more space for installation.

4. Shrink capsule machines

Operation: This type of machine is specifically designed to apply shrink capsules, which are heated and "shrink" onto the neck of the bottle to form a perfect seal.

Features: The process involves inserting the capsule onto the bottle, which is then passed through a heat tunnel or directly heated on the bottle using resistances. The capsule fits perfectly to the neck of the bottle.

Advantages: Provides a secure and professional seal, and is ideal for products such as wine, champagne, and other carbonated beverages that require additional protection against tampering.

Disadvantages: Requires specific heating equipment, which increases costs and process complexity.

5. Pressure or compression capping machines

Operation: In these machines, the capsule (often aluminum or plastic) is applied through a pressure system that secures the capsule around the neck of the bottle. Some models may also include a heating system to soften the capsule before compression.

Features: Mainly used for aluminum capsules or PVC capsules, these machines are suitable for bottles with crown or screw caps.

Advantages: Speed and simplicity of the process, with good sealing quality.

Disadvantages: Limited to capsules of certain materials and types of bottles.

6. Shrink-sleeve capping machines

Operation: These machines are used to apply shrink sleeves around the neck of the bottle. The sleeve is typically a sheet of plastic material that is heated to adhere perfectly to the shape of the bottle.

Features: Suitable for a wide variety of bottle formats and capsules, these machines are mainly used for bottles that require a security seal and a distinctive visual appearance.

Advantages: Suitable for different bottle formats, ensuring a secure seal and an attractive aesthetic.

Disadvantages: Longer process compared to traditional shrink capsule machines, and higher costs.

ROBINO & GALANDRINO